Table of contents

- Why Safety Compliance Matters

- Laying the Groundwork for Compliance

- Leadership Drives Change

- Engage and Train Every Employee

- Identify and Manage Risks

- Leverage Technology for Safety

- Keep Up with Audits and Inspections

- Cultivate a Culture of Safety

- Learning from Real-World Success

- Common Pitfalls and How to Avoid Them

- The Road Ahead

In today’s rapidly moving and dynamic world of industry, improving safety compliance in its industries, is more than a legal obligation; it creates trust amongst employees, reduces costs, and increases productivity. Companies and organizations value safety, as this allows them to protect people and assets alike. We offer this guide outlining the pathways to improve safety processes.

Why Safety Compliance Matters

Safety compliance protects your workers. It reduces accidents and near misses. It also protects your brand. There are regulators across the global that enforce serious rules. Following the rules shows you value people more than profits. It can reduce your downtime and it can reduce your insurance costs. Achieving safety compliance in industry opens a path to long-term success.

Laying the Groundwork for Compliance

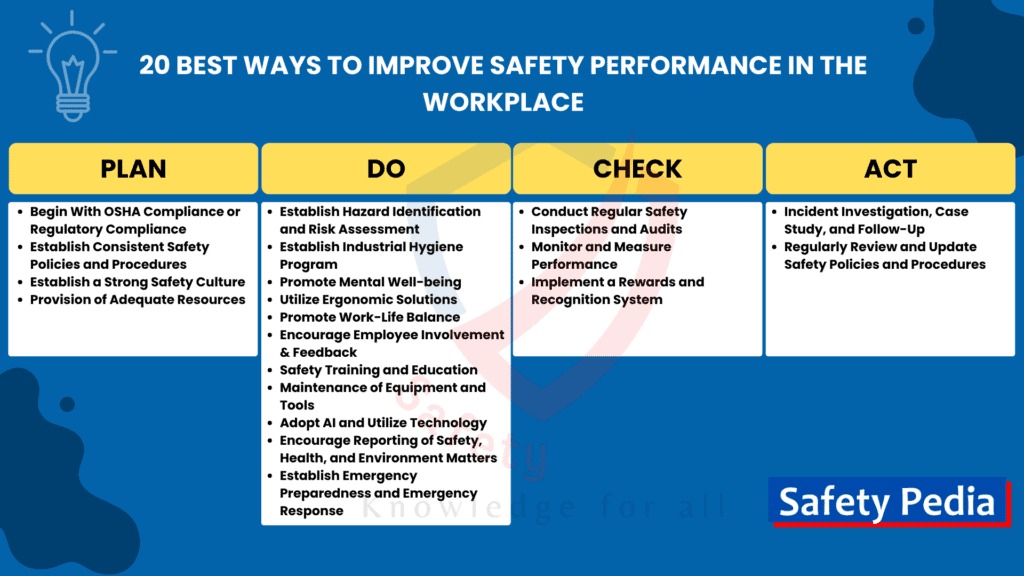

Before you do anything, take the time to learn some key regulations – local, national, and international standards documents. Study OSHA rules, or review ISO 45001 instructions. Map your processes against them. Identify where you fulfill the requirements, and then identify the gaps that need work (and put things in place to fix). Doing this first makes the later improvements clearer and faster.

Leadership Drives Change

Leadership establishes the environment for safety. The very act of walking the shop floor sends a message. It’s a caring message. Trust is established by leaders and managers who share safety as a topic of discussion. They are the ones who set aside the budget for training, gear, and tools found in industry. Their active participation in supporting safety creates a high level of potential motivation for the team. The commitment to advancing safety compliance in industry can only be achieved under the direction of leadership.

Engage and Train Every Employee

Safety is everyone’s job. Offer regular, hands-on training. Use short videos, role-play, and quizzes. Keep the sessions under an hour. Tailor training to each role. Encourage questions. Reward workers who spot hazards. When staff own safety, compliance improves. Consistent training builds habits, not just checklists.

Identify and Manage Risks

Risk assessment is central to compliance around safety. Identify all the tasks. Identify all potential hazards. Assess likelihood of each hazard. Assess the potential severity of any harm. Use basic scoring to ascertain this: low, medium, high. Start with high risk areas first. Then you design control measures. Review control measures regularly. What this creates is a cycle of assessing and action which will be more dynamic about managing risk and working towards safety compliance.

Leverage Technology for Safety

Digital tools can change safety compliance practices. Sensors can monitor temperature, noise, and chemical or gas leaks. Real-time incident tracking can be done using mobile apps. Wearable technology can monitor workers’ vitals. Automated alerts can be sent to employees about hazards. Dashboards can visualize trends in safety compliance. These are really helpful to inform decision-making. They can help to reduce paperwork, and simplify response time. Digital technology solutions are essential for improving safety compliance in an industry to-day.

Keep Up with Audits and Inspections

Regular audits can keep small issues from maturing into something much bigger. Use internal inspectors but consider also using a third-party inspector. Review records. Walk the floor. Test equipment. Verify people have attended training in records. Document these findings. Assign clear series of actions and deadlines. Follow up on these actions until completed. Consistent auditing is a clear message to employees that safety is a priority and there are required actions.

Key Strategies at a Glance

| Strategy | Benefit | Action Step |

|---|---|---|

| Leadership Commitment | Inspires a safety-first culture | Schedule weekly safety walk-arounds |

| Employee Training | Builds knowledge and confidence | Launch 30-minute monthly refreshers |

| Risk Assessment | Targets hazards efficiently | Conduct quarterly risk scoring sessions |

| Technology Integration | Enhances real-time visibility | Deploy sensors and mobile reporting apps |

| Audits and Inspections | Ensures ongoing compliance | Set audit calendars with clear owners |

Cultivate a Culture of Safety

Policies are essential but it is the culture that holds them in place. Celebrate successes with safety. Tell stories of what could have happened in near-miss events to strengthen the teachings and lessons. Recognize teams when they have met safety goals. Set up simple suggestion boxes, whether digital or physical, and allow anonymous stereos. Show that you act on suggestions. When workers feel valued and feel they are being heard, they remain alert and engaged. A solid safety culture assists with increasing safety compliance in industry by making safe behaviors feel normal.

Behavioral Safety Observations

People create safety just as much as policies do. Implement a behavioral observation program. Train observers, often themselves employees, to observe tasks and identify safe or unsafe behaviours. Feedback should be reinforcing and immediate. Report on the trends without names. This honest feedback captures hidden risks and promotes personal ownership of safety; one of the most difficult factors to improve to understand how to improve safety compliance in industry.

Transparent Communication

When you speak clearly you build trust. Talk safety every week-expectations, successes, and safety challenges. Use simple emails, bulletin boards, or team huddles. Allow for open dialogue-no blame. When workers report a hazard, thank them! Then show them how you fixed that hazard. Show transparency and you transform safety into team responsibility.

Visual Management Tools

A picture is worth a thousand words. Use posters, floor decals, or color-coded signs to communicate hazards and safe routes. Label walkways, danger zones, and emergency equipment. Use “quick reference” charts to show PPE (personal protective equipment) rules. Visual reminders improve safety knowledge retention and decrease reliance on verbal reminders.

Integrating Sustainability and Safety

Green practices can increase safety, too. Switch to non-toxic cleaners. Use energy-efficient lighting to resolve glare. Recycle leftover materials to decrease clutter. Doing these things can reduce hazards and still accomplish your environmental objectives. All of this work shows what happens when safe practices are coupled with sustainability, resulting in a healthier workplace and smaller green footprint.

Harnessing Virtual Reality for Training

Virtual reality (VR) provides safe, immersive practice. Workers step into digital duplicates of the shop floor. They learn to identify hazards in situ, without real risk. VR offers practice that is also fun and memorable. Early adopters report developed retention of knowledge and fewer on-site errors, a great way to improve safety compliance behavior in industry.

Learning from Real-World Success

A mid-sized manufacturer lowered injuries by 40% within one year. How? They used hands-on training in conjunction with a mobile incident-reporting application. Managers would review reports each morning. They acted on hazards within 24 hours. Quarterly audits reviewed progress. They shared the data publicly. The combination of training, technology, and transparency was what propelled their success in improving safety compliance in industry.

Common Pitfalls and How to Avoid Them

Avoid these traps:

- Treating safety as a form to fill out.

- Skipping follow-up on audit findings.

- Overloading staff with jargon.

Instead, keep language simple. Close the feedback loop. Make safety checks quick but thorough. Focus on clear, actionable steps. This approach keeps safety practical, and workers engaged.

The Road Ahead

Improving safety compliance in industry is not a one-time endeavor. It’s a continual endeavor. Stay current with changes in regulations and technological advancements. Keep training timely and relevant. Use data to identify evolving risks. Make changes to your policies as you learn. Each of these initiatives adds nuance to your safety program on an annual basis.